Steel Connections As Per IS 800-2007

- Steel Connection as per IS 800-2007 consist of components such as cleats, gusset plates, brackets, connecting plates and connectors such as rivets, bolts, pins, and welds.

- The connections in a structure shall be designed so as to be consistent with the assumptions made in the analysis of the structure and comply with the requirements specified in this section.

- Steel Connection as per IS 800-2007 shall be capable of transmitting the calculated design actions. Cl. No.10.1.1 [IS 800-2007]

- Where members are connected to the surface of a web or the flange of a section, the ability of the web or the flange to transfer the applied forces locally should be checked and where necessary, local stiffening provided. No.10.1.2 [IS 800-2007]

- Ease of fabrication and erection should be considered in the design of connections.

- Attention should be paid to clearances necessary for field erection, tolerances, tightening of fasteners, welding procedures, subsequent inspection, and surface treatment md maintenance. No.10.1.3 [IS 800-2007]

- The ductility of steel assists the distribution of forces generated within a joint.

- Effects of residual stresses and stresses due to tightening of fasteners and normal tolerances of fit-up need not therefore be considered in connection design, provided ductile behaviour is ensured. No.10.1.4 [IS 800-2007]

- In general, use of different forms of fasteners to transfer the same force shall be avoided.

- However, when different forms of fasteners are used to carry a shear load or when welding and fasteners are combined, then one form of fastener shall be normally designed to carry the total load.

- Nevertheless, fully tensioned friction grip bolts may be designed to share the load with welding, provided the bolts are fully tightened to develop necessary pretension after welding. No.10.1.5 [IS 800-2007]

- The partial safety factor in the evaluation of design strength of connections shall be taken as given in Table 5 [IS 800-2007] (Cl. No.10.1.6)

Location Details of Fasteners: (Cl. No.10.2):

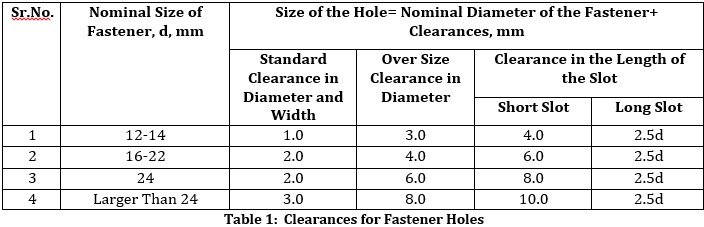

Clearances for Holes for Fasteners: (Cl. No.10.2.1):

Bolts may be located in standard size, over size, short slotted or long slotted hole.

a)Standard clearance hole:

• Except where fitted bolts, bolts in low-clearance or oversize holes are specified, the diameter of standard clearance holes for fasteners shall be as given in Table 1.

b)Over size hole:

• Holes of size larger than the standard clearance holes, as given in Table 1 may be used in slip resistant connections and hold down bolted connections, only where specified, provided the oversize holes in the outer Ply is covered by a cover plate of sufficiently large size and thickness and having a hole not larger than the standard clearance hole (and hardened washer in slip resistant connections).

c)Short and long slots:

• Slotted holes of size larger than the standard clearance hole, as given in Table 1 may be used in slip resistant connections and hold down bolted connections, only where specified, provided the oversize holes in the outer ply is covered by a cover plate of sufficiently large size and thickness and having a hole of size not larger than the standard clearance hole (and hardened washer in slip resistant connection).

Minimum Spacing: (Cl. No.10.2.2):

• The distance between centers of fasteners shall not be less than 2.5 times the nominal diameter of the fastener.

Maximum Spacing :(Cl. No.10.2.3)

• (Cl. No 10.2.3.1) The distance between the centres of any two adjacent fasteners shall not exceed 32t or 300 mm, whichever is less, where tis the thickness of the thinner plate.

• (Cl. No.10.2.3.2) The distance between the centres of two adjacent fasteners (pitch) in a line lying in the direction of stress, shall not exceed 16t or 200 mm, whichever is less, in tension members and 12t or 200 mm, whichever is less, in compression members; where r is the thickness of the thinner plate.

• In the case of compression members wherein forces are transferred through butting faces, this distance shall not exceed 4.5 times the diameter of the fasteners for a distance equal to 1.5 times the width of the member from the butting faces.

• (Cl. No.10.2.3.3) The distance between the centers of any two consecutive fasteners in a line adjacent and parallel to an edge of an outside plate shall not exceed 100 mm plus 4t or 200 mm, whichever is less, in compression and tension members; where t is the thickness of the thinner outside plate.

• (Cl. No.10.2.3.4) When fasteners are staggered at equal intervals and the gauge does not exceed 75 mm, the spacing specified in Cl. No.10.2.3.2 and Cl. No.10.2.3.3 between centers of fasteners may be increased by 50 percent, subject to the maximum spacing specified in Cl. No.10.2.3.1.

- You might be interested in reading this post

- LIMIT STATE METHOD OF DESIGN- IS 800-2007

7